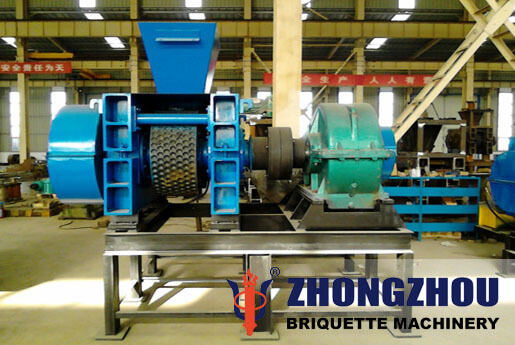

Based on practical experience, the material pressure rate: metallurgical slag classes, gypsum, dry materials, all use hydraulic high pressure briquetting machine, its pressure is big, molding density is high, high balling rate, good appearance, save the cost of the binding agent, andreduce costs. Active pressure generated by the hydraulic system, apart from other passive pressure.

The entire hydraulic system of dual-use briquetting machine hydraulic system and accumulator of hydraulic and constant pressure play a role to ensure the function of forming pressure, the decency reliable operation and easy maintenance, hydraulic cylinder structure is the structuralstyle according to several tests of the company based on several experience in the production of briquetting machine.

Currently my company has designed a new type of dual-use pressure briquetting machine of hydraulic constant pressure, mainly adopt the production of the hydraulic system during normal wokring. But if the hydraulic system fails, or the cold weather, the oil pump failed to start. Youcan convert hydraulic constant pressure and continue to work. Repair the hydraulic system in the case of normal production. After fixing, continue to convert to the hydraulic system (in alpine region, in winter the machine must be converted to a constant voltage for long-term work).

In addition, the circuit is matched with accumulator, in order to ensure the protection circuit when the system pressure and the piston back. Hydraulic pump station take DBD series motor oil pump, the pump together with self-contained fuel tank pressure gauge and a variety ofapplications valve, the major works of the pump is driven by the motor oil and a stable thrust, when the feed is too large, the two on the roll center distance will increase by anti-pressure cylinder piston and then shift, resulting in increased system pressure, and the pressure of the oil return accumulator to ensure the safety of the running.

Position:

Position: