The sludge briquette press machine, sludge briquetting machine is usually used in the following situations:

1.Compress industrial sludge and metal shavings into pellets/briquettes suitable for blast furnace use.

2.Sludge is a byproduct produced in the steel production process, such as blast furnace sludge, gas sludge, steel rolling sludge, etc.

3.The main components of sludge are usually iron oxide and calcium oxide, and may also contain oxides such as silicon dioxide, magnesium oxide, and aluminum oxide.

The sludge briquette press not only helps environmental protection by converting sludge into useful pellets/briquettes, but also increases the added value of materials, making it an effective solution for industrial waste treatment and resource recovery.

Working principle of sludge briquette Machine:

Feeding: The powdered material is first fed into the briquettel press through the feeding device.

Pressing: The material enters the forming area of the briquette pressing machine and is compressed under high pressure.

Forming: The compressed material is pressed into the desired shape of briquettes in a model (usually a forming plate with specific shaped grooves).

Demolding: The pressed briquettes are pushed out of the model through mechanical or hydraulic means.

Transportation: The formed briquettes are sent out through conveyor belts or other conveying equipment for the next step of drying, roasting, or direct use.

Adjustment: Briquette pressing machines are usually equipped with adjustment devices that can adjust parameters such as pressing pressure and material moisture content to achieve the best molding effect.

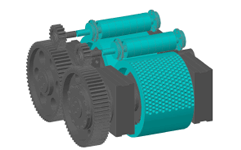

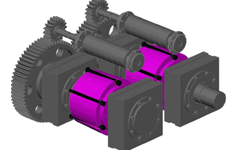

Sludge briquetting machine structure

1. The feeding part mainly realizes quantitative feeding to ensure that the material enters the pair of rollers evenly. If the feeding amount is too large, the electric power of the feeding device will be overloaded; if the feeding amount is too small, the goal will not be achieved. Therefore, skilled operation skills are an important condition to ensure the normal operation of the briquettes.

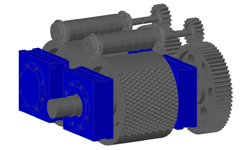

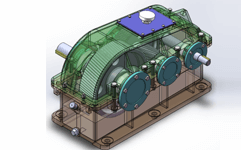

2. For the transmission part, the main transmission system is: motor-delta belt — reducer-open gear — roller.

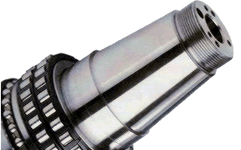

3. The forming part mainly refers to the main part, and the core part is the roll. The machine can adjust the pressure according to the requirements of the briquette density, and the production is flexible.

Material requirements for sludge briquette press machine

1. The particle size of the material should be controlled within 30-40% of 1mm, with particles ranging from 1mm to 2mm accounting for 30-40%. All particle sizes should be less than 3mm.

2. The moisture content should be controlled between 8-10%, as excessive moisture can affect the briquette forming effect.

3. The material must not contain iron briquette or other high hardness impurities to avoid damaging the stick and shaft of the briquette press.

Advantages of sludge briquette press

1. Volume reduction: The briquette pressing process can reduce the volume of sludge, making it more economical and effective for transportation and storage.

2. Resource recycling: Depending on the materials involved, the briquettes made can sometimes be recycled or reused.

3. Environmental impact: By reducing waste volume and promoting appropriate treatment or recycling, sludge briquette presses contribute to environmental sustainability.

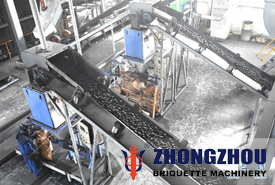

The flow chart of sludge briquettes production line:

The sludge briquettes process generally include batching, grinding, mixing, sludge briquetting machine/briquette machine and drying.

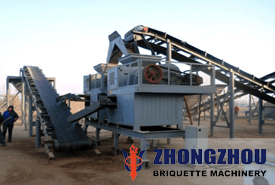

1. Hopper silo, or box type quantitative feeder, it load and convey raw materials to crusher evenly.

2. Two-stage crusher, the raw material be crushed in to the appropriate size, generally it is most suitable that not more than 5mm.

3. Liquid mixer, be used for mixing liquid binder, if use powdered binder, it should use a drying powder feeding equipment.

4.Horizontal two shafts mixer, evenly mixing raw materials, adhesives andwater together, the adhesive will be evenly distributed in the raw materials so that achieve better strength, making briquettes better.

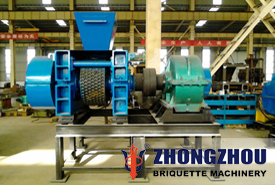

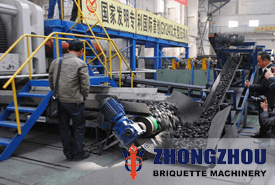

5. Sludge briquette machine/briquetting machine is a core of whole production line, it press materials into briquettes, the briquettes' size and shape can be customized, zhongzhou can produce various shapes of rollers.

6, vertical dryer, drying the wet briquettes which came from briquette machine,the briquettes can be dried to 3% water content, finished briquettes will put in storage or packaged.

7, belt conveyor, connected to devices, it is guanrantee for the whole manganese ore briquettes production line to realizes full automation.

Please feel free to contact our company for consultation. If you are interested in sludge briquette machine and its technical guidance:

ZHENGZHOU ZHONGZHOU BRIQUETTE MACHINERY PLANT,

Tel:+86 15890078925 13783550028

F-mail: zzbriquettemachine@dzzzg.cn

Website: www.zz-briquette-machine.com

Zhongzhou sludge briquette machine/briquetting machine is specifically designed for briquetting industrial sludge, it has high productivity, high degree of automation, production efficiency,low failure rate, easy maintenance, so Zhongzhou sludge briquette machine/briquetting machine was welcomed by many enterprises at home and abroad.

Position:

Position: .jpg)

Description

Description

Parameter

Parameter

Advantages

Advantages

Cases

Cases

.jpg)

.jpg)

.jpg)

.jpg)