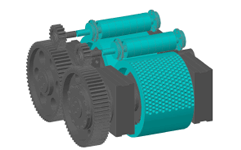

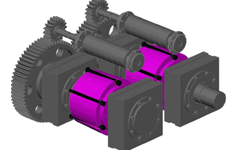

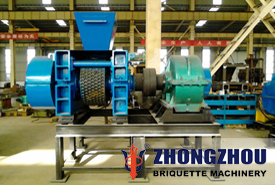

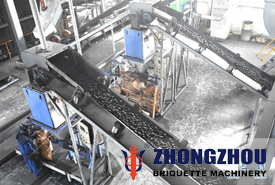

Brief Introductions of Zhongzhou carbon black briquette machine:

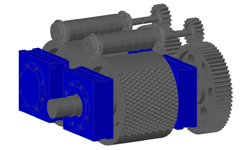

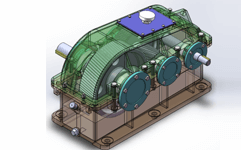

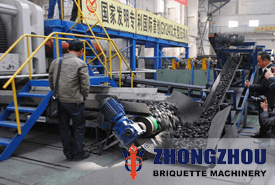

Zhongzhou carbon black briquette machine also can be used for briquetting carbon black, black lead, graphite, plumbago,It is worth noting that need special adhesive as binder in briquetting process, that will be very important for density of carbon black briquettes, customer should consult with binder supplier and then order briquette machine, Zhonghou carbon black briquette machine is specialized for pressing carbon black, hydraulic systerm, four rollers double pressure can effectively work for raw materials, they can press briquettes of various shapes like square, round, oval, pillowed etc, or we can manufacture what you required, the briquette size shall be in Φ20-80mm.

The advantages of Zhongzhou carbon black briquette machine:

1. High profit and low cost in raw material.

2. Increase the net calorific value per unit volume after briquetting.

3. Energy saving, friendly-environment, Low-consumption.

4. No chemical additives, no smell, no smoke.

5. Easy to transport and store as densities product.

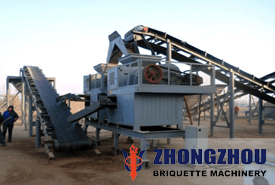

The requirement for raw materials of carbon black briquettes production:

1) the particle size of the raw material should be between 0-5mm.

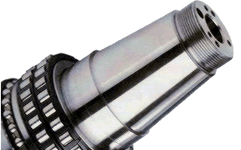

2)can not contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle..

3) the feeding of whole produciton line should be stable, even, ensure workloads of briquette machine stable, to get high efficiency of production.

Zhongzhou company based on metallurgical briquette machine technical services, to create maximum value for clients, The carbon black briquette machine we produced has the high pressure, high finished product rate, high strength, optimized operation, create the conditions for the realization of maximum benefit, we sincerely welcome all enterprises to explore, mutual benefit and win-win!

Position:

Position:

.jpg)

Description

Description

Parameter

Parameter

Advantages

Advantages

Cases

Cases

.jpg)

.jpg)

.jpg)

.jpg)