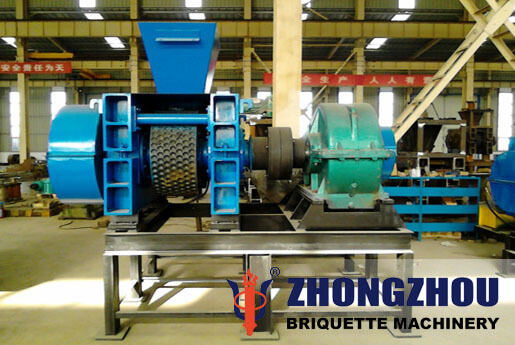

The equipment of briquettes production line is a set of assembly line equipment, its main processing equipment is briquette machine, so we must first understand the whole testing machine process of the briquette machine and its ancillary equipment:

1. A full-time electrician complete the various electrical links. Ensure briquette machine steering motor turn consistent (forward), then put on the V-belt to commission empty.

2. If you configure the encryption machine, adjusted encryption machine steering, guaranteed to be forward, adjust the gap of the two rollers, until satisfaction putting out.

3. Adjust briquette machine center bracket docking conveyor belt, and then adjust the conveyor belt tightness and empty test turn.

4. Adjusted briquette machine steering, guaranteed to be forward, to observe the out ball condition, no roll banding phenomenon. If so respond to forming roller polishing, dry bulk coal on a stiff, pressure test is repeated until all stripping.

5. First the briquetting machine press balls,then natural dry, when the furnace temperature rise to 200 degree, by the conveyor,the briquetting machine begins to feed to dryer, at the same time open discharging water-gate on the bottom of the dryer to begin to emit dry bulbs. The discharging port size should be matched with the briquetting machine's feeding amount. Observe the dry and wet condition, if the drying efficiency is not good, and there is still wet balls, users should increase air output to improve the furnace temperature, otherwise reduce air output to reduce the furnace temperature, until the result is best.

6. The water content of the raw material is not greater than 7%. Adjust the feed rate, should be determined according to the situation of the ball,strength best is standard.

Position:

Position: