Role of Pump for ZHONGZHOU Hydraulic Briquetting Machine

Share Us:

Date:2018-01-08

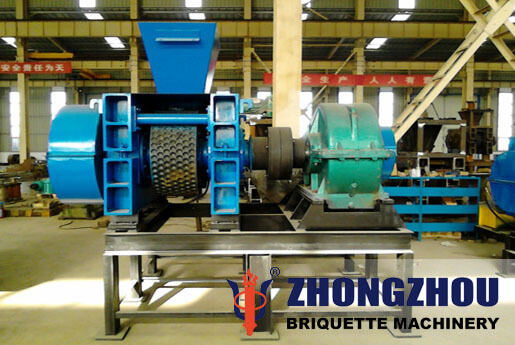

Hydraulic briquette machine, also named as hydraulic briquetting machine, is able to suppress mineral powder, metal powder, pulverized coal, coke powder and other materials into balls. Hydraulic pump is one of the key parts in hydraulic briquette machine. By mean of hydraulic pump, high-pressure oil is pumped into hydraulic cylinder and push the piston forward.

To meet the pressure demand for production, front connector of piston rod bears against the bearing seat. If materials are too many between two press rollers or metal blocks exist in materials, piston rod will be excessively pressed. Hydraulic pump will stop working. Energy accumulator will play the role as buffer.

The displacement of piston rod will widen the distance between press rollers. Hard objects can easily pass through press rollers. System pressure backs to normal and protects the press roller from being damaged. You can adjust the working pressure of hydraulic briquetting machine according to the demands for briquette density.

With features of high working efficiency, strong working capacity and long service life, hydraulic briquetting machine is a good helper for you to deal mineral wastes. Quality rooted, product will be excellent. With three state-level machinery research institutions and more than 50 national patents, Zhongzhou has established favorable relationship with departments of science and technology.

All these enables the leadership of Zhongzhou in mining machinery manufacturing industry. Therefore, Zhongzhou products are worthy of trust, welcome to leave a message!

Inquiry

*Describe your buying requirements in detail

Please enter your demand such as Raw material type, Capacity, Feeding material size, briquettes' size and shape. Any other requirements and questions about the machines, you can also contact online or leave a message, we will offer you a perfect proposal!

Position:

Position: