Key Factor for Gypsum Briquetting Machines’ Good Performance

Share Us:

Date:2017-05-23

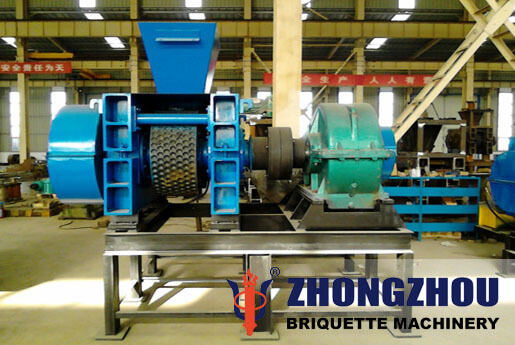

The desulfurization gypsum briquette machine is one of the most important devices in the briquetting plant. Technically speaking, there are many factors influencing the performance of the gypsum briquetting machine. These factors include press roller distance, raw material granularity, binding agent, water content, drying temperature and working time etc.

Among so many factors, the press roller distance may be the most significant one. As long as we keep the best roller distance, we can make our desulfurization gypsum briquette machine create the finished products that meet and even exceed the standard requirement. Today professionals from Fote Machinery will analyze the influence of the press roller distance on the performance of the briquetting machine and then offer the effective solution to realize the best distance.

For the desulfurization gypsum briquette machine, the roller distance is inversely proportional to the compression ratio. That is to say: decrease the roller distance will increase the briquetting pressure. However, once the distance between the upper and lower rollers is too small, it will cause raw materials unavailable to fill in the ball bowls, thus affecting the product quality. Once the distance is too large, raw materials will fall down soon before the briquetting pressure starts to access to the bowl center, thus affecting the product strength, leading to thick, rough edged and broken materials. Even briquetting failure will happen.

Therefore, when installing the double rollers of the gypsum briquetting machine, namely the upper roller and the bottom roller, users need to pay attention to the installing distance between them. In general, the distance can be set within 2-3 mm. Be careful that the ball bowls on each roller should be matched accurately in case that the false mold will harm the final product strength.

If you are interested in Zhongzhou briquette machines, visit our website: www.zz-briquette-machine.com or send emails to zzbriquettemachine@dzzzg.cn. We will contact you as soon as possible.

Inquiry

*Describe your buying requirements in detail

Please enter your demand such as Raw material type, Capacity, Feeding material size, briquettes' size and shape. Any other requirements and questions about the machines, you can also contact online or leave a message, we will offer you a perfect proposal!

Position:

Position: