Superior Features of Charcoal Briquette Machine

Share Us:

Date:2018-01-11

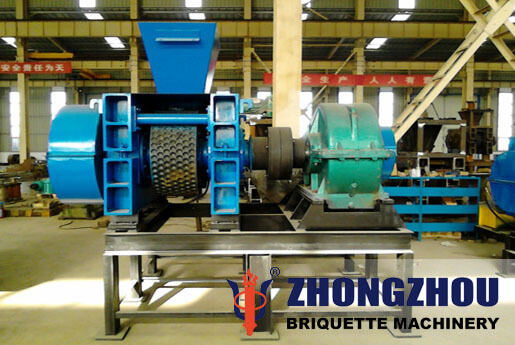

Charcoal briquette machine, which can help you to turn coal wastes into products of great value, is becoming more and more popular around the world market. Then, the following content will discuss about the superior feature of charcoal briquetting machine. Through the quantitative device, materials in bin are evenly delivered to the hopper.

Then, under the work of adjusting blades on hopper, raw materials are evenly delivered to the distance between rollers. Pressure of rollers, which run at same speed and toward converse direction, changes from smaller to larger. The pressure of roller reaches to the summit at center line.

After materials pass this line, forming pressure suddenly becomes small and makes briquettes get out of ball socket. Charcoal briquettes making machine is used to suppress the wastes like iron powder, mineral powder, scale, steel slag and refractory materials.

The roller skin is made of 65 manganese. After being specially treated with heat, hardness of roller skin can reach to more than 58℃. Zhongzhou technicians adopt the combining assembly to make roller skin, so it is easy to be changed after being worn out. After the special heat treatment, hardness of roller skin can better protect the charcoal briquette machine from being hit by hard objects.

Buffering device, being installed in charcoal briquetting machine, can protect the machine from being hit by hard objects. Leave your project background on website to get details!

Inquiry

*Describe your buying requirements in detail

Please enter your demand such as Raw material type, Capacity, Feeding material size, briquettes' size and shape. Any other requirements and questions about the machines, you can also contact online or leave a message, we will offer you a perfect proposal!

Position:

Position: