Working Technology of Hydraulic Briquetting Machine

Share Us:

Date:2018-01-08

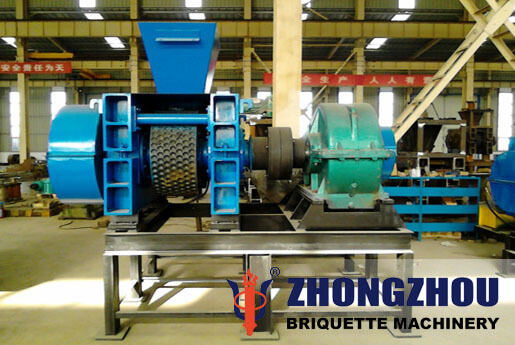

Hydraulic briquetting machine, also called hydraulic briquette machine, is a machine that can deal a lot of mineral powders for one time. It is an urgent task to develop the working technologies of hydraulic briquetting machine. During the process to make mineral briquettes, hydraulic briquetting machine may sometimes discharge the coarse balls.

How to solve this problem? As a supplier of hydraulic briquetting machine, ZHONGZHOU briquetting machine manufacturer can offer the solutions for you. Work of hydraulic briquetting machine includes the technologies like additive addition, medium and low pressure, no-drying and cold briquetting.

Through electromagnetic speed motors, power is offered by dynamo. Then, through belt pulley, cylindrical gear reducer and coupling, power is delivered to the driving shaft. By means of open gear, driving shaft and driven shaft can run synchronously. Behind the bearing saddle, there is a hydraulic device.

Driven by the electromagnetic speed motors, spiral feeder delivers the raw materials to major feeding mouth through belt pulley and worm reducer. Electromagnetic speed motors have the feature of constant torque. If material amount in spiral feeder is equivalent to the desired amount of dynamo, feeding pressure will be constant and briquette quality will be stable.

If feeding amount is too heavy, electricity of feeder will be overloaded. While, if feeding amount is too small, briquettes will be hard to be produced. Skillful operation is an important situation to ensure the normal work of hydraulic briquetting machine. Click website to download the Free PDF of hydraulic briquetting machine!

Inquiry

*Describe your buying requirements in detail

Please enter your demand such as Raw material type, Capacity, Feeding material size, briquettes' size and shape. Any other requirements and questions about the machines, you can also contact online or leave a message, we will offer you a perfect proposal!

Position:

Position: