use common sense of briquette machine

Share Us:

Date:2017-01-08

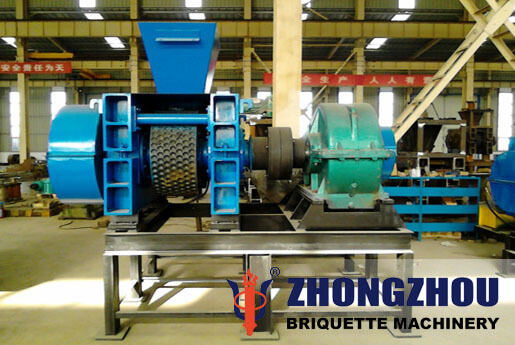

Briquette machine/ briquette making machine mainly consists of a frame (or a underchassis), speed reducer, upper and lower frame, spindle seat,main spindle, main bearing, coupling, king roller, side roller, wheel hub, main driven gear, ball socket deviation adjuster, bearing seat, main assemblage of papilionaceous springs, oil cylinder, piston, oil pump, feeding funnel and output belt.

Raw materials by its own gravity from feed inlet to the middle of two rollers, two pressure roller surface evenly distributed identically shaped roll groove, two press rolls counter-rotating at the same speed, raw materials entering the groove is forced to compress. With the roll continues to rotate, briquettes falling under gravity.

Please check the following below before the no-load running:

● Check and make sure the installed bolts of the principle machine and the anchor screw has been screwed

down;

● Check the lubricating oil mass of the speed reducer, feeder machine and the lubricating parts of the

principle machine;

● Check the tightness of the triangle belt;

● The standard oil pressure;

● Turn the triangle belt by hand and make sure no eyewinker and unmoral conditions in the double-roller

bunker and the implement; Strictly follow the sequence of the notice of starting machine, pay great attention to the

notice of the hydraulic pressure oil pump ,principle machine and feeder machine in no-load running.

● Check if there is unmoral noises and check the temperature up of the rotation parts;

● Check the operation direction of the electric machine, the left side installed electric machine turns left,

otherwise right.(Monitoring when the speed is down)

● Check the running condition of the triangle belt, not too loose or too tight. The ball press can be used for

production after the normal no-load running .

2-3 After the normal load running and no-load running, the load test run can be operated. Firstly, check

if there is eyewinker in the double-roller. The starting of loading material is forbidden. The starting sequence is

hydraulic pressure oil pump-principle machine-feed operation.

When running, pay attention to the below:

● Check if there is any abnormal rotation noises, loose bolt and the abnormal temperature up of bearing

● Check the electrical degree of every electrical machine

● Check if the oil pressure is normal

● No hard things like metal in the feed

Zhengzhou Zhongzhou Briquette Machinery Plant is a 24 years manufacturer specialized in produce briquette machine,mixer, crusher, and drying equipment in China. The product also be showed on Alibaba.com, own 7 yeras VIP enterprise, get the certification of high-integrity enterprise by Alibaba. Zhongzhou briquette machinery welcome your visiting!

Inquiry

*Describe your buying requirements in detail

Please enter your demand such as Raw material type, Capacity, Feeding material size, briquettes' size and shape. Any other requirements and questions about the machines, you can also contact online or leave a message, we will offer you a perfect proposal!

Position:

Position: