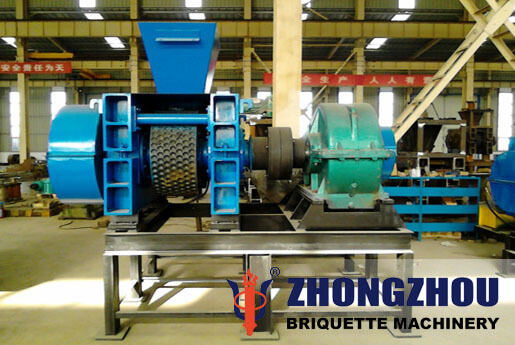

Inner Structure of Iron Powder Briquette Machine

Share Us:

Date:2018-01-10

For good briquetting machines, their internal structure must be reasonable. Here, we make a detailed introduction on inner structure of iron powder briquette machine. Constant feeder ensures raw materials are evenly delivered into distance between double rollers. Auxiliary roller suppresses the raw materials offered by hopper and then deliver them to main roller for further briquetting.

Power, offered by main dynamo, is transmitted to driving shaft through pulley belt, gear accelerator and coupling. Driving shaft and driven shaft can work synchronously through open gear. Behind the active bearing, there is a pressure unit which can adjust the distance between driving roller and driven roller.

When materials in press rollers are many or mixed with metal briquettes, tapered iron can automatically move upward, recover the system pressure and protect the press roller from being damaged. Driven by the dynamo, two wheels run at same speed but toward different directions.

When raw materials fall into the two wheels and are suppressed, they are condensed in the distance between two ball sockets. Along with the gradual revolution of wheels, ball sockets gradually close and briquetting pressure gradually increases. When the distance between two ball sockets is at minimum, molding pressure is at the maximum.

Then, wheels move and ball sockets are gradually far away from each other, molding pressure rapidly decreases. Before molding pressure becomes zero, mineral powders begin to inflate. Demolding rate of iron powder briquetting machine is 100% and balling rate is 90% higher.

Inquiry

*Describe your buying requirements in detail

Please enter your demand such as Raw material type, Capacity, Feeding material size, briquettes' size and shape. Any other requirements and questions about the machines, you can also contact online or leave a message, we will offer you a perfect proposal!

Position:

Position: